The Hidden World of Automotive Paint Protection

The gleaming, flawless finish of a newly painted car is a sight to behold. But how does that perfect sheen remain unblemished against the onslaught of environmental hazards? Welcome to the fascinating realm of automotive paint protection, where cutting-edge science meets the art of preservation. This often-overlooked aspect of vehicle care has evolved into a sophisticated industry, employing advanced materials and techniques to shield our prized possessions from the ravages of time and nature.

As the automotive industry grew, so did the demand for more durable and aesthetically pleasing finishes. The introduction of nitrocellulose lacquers in the 1920s marked a significant leap forward, allowing for faster application and a glossier finish. However, these early synthetic paints still lacked long-term durability and required frequent polishing to maintain their luster.

The post-World War II era saw the advent of acrylic lacquers and enamels, which offered improved durability and color retention. But it wasn’t until the 1970s that a true revolution occurred with the introduction of two-stage urethane paints. These finishes consisted of a pigmented base coat followed by a clear coat, providing unprecedented protection and shine.

The Science Behind Paint Protection

Modern automotive paint protection is a multi-layered approach that combines chemistry, materials science, and nanotechnology. At its core, paint protection aims to create an invisible barrier between the vehicle’s paint and external threats such as UV radiation, acid rain, bird droppings, tree sap, and road debris.

One of the most significant advancements in this field has been the development of ceramic coatings. These liquid polymer solutions bond chemically with the vehicle’s factory paint, creating a semi-permanent layer of protection. The science behind ceramic coatings involves the use of silicon dioxide (SiO2) or titanium dioxide (TiO2) nanoparticles, which form a dense, cross-linked network when cured.

This microscopic layer not only provides exceptional hardness and durability but also exhibits hydrophobic properties, causing water to bead up and roll off the surface. The result is a self-cleaning effect that helps maintain the vehicle’s appearance with minimal effort.

Advanced Film Technologies

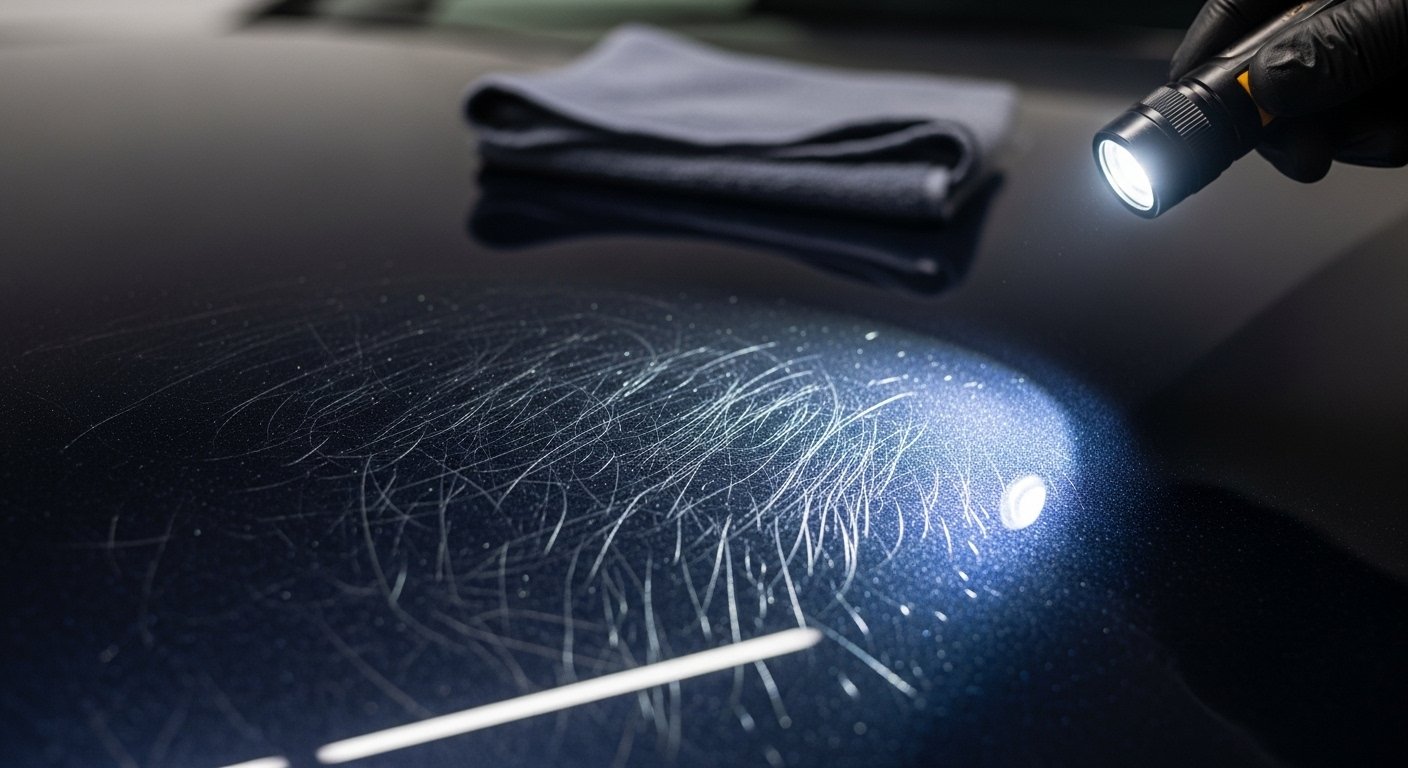

While ceramic coatings offer excellent chemical resistance, they provide limited protection against physical impacts. This is where paint protection films (PPF) come into play. These thermoplastic urethane films are the result of decades of research and development, originating from military technology used to protect helicopter rotor blades from debris.

Modern PPFs are marvels of material engineering, combining optical clarity with self-healing properties. When scratched or scuffed, these films can “heal” themselves through the application of heat, effectively erasing minor damage. The latest generation of PPFs also incorporates hydrophobic top coats, merging the benefits of ceramic coatings with physical impact resistance.

Nanotechnology and Smart Coatings

The frontier of automotive paint protection lies in the realm of nanotechnology and smart coatings. Researchers are developing coatings that can actively respond to environmental stimuli, changing their properties to provide optimal protection under various conditions.

One exciting area of research involves the use of shape-memory polymers in paint protection films. These materials can “remember” their original shape and return to it when triggered by heat or light. This could lead to self-repairing coatings that can smooth out dents and scratches autonomously.

Another promising development is the integration of photocatalytic nanoparticles into paint protection coatings. These particles, typically made of titanium dioxide, can break down organic contaminants when exposed to sunlight, effectively keeping the vehicle’s surface clean and free from pollutants.

The Environmental Impact

As the automotive industry moves towards more sustainable practices, paint protection technologies are also adapting to meet environmental concerns. Traditional solvent-based coatings are being phased out in favor of water-based and low-VOC (Volatile Organic Compound) alternatives.

Moreover, the longevity provided by advanced paint protection systems contributes to sustainability by reducing the need for repainting and extending the aesthetic lifespan of vehicles. This not only conserves resources but also minimizes the environmental impact associated with automotive refinishing processes.

The Future of Automotive Aesthetics

The world of automotive paint protection is rapidly evolving, with new technologies promising to revolutionize how we maintain and enhance our vehicles’ appearances. From self-cleaning surfaces to coatings that can change color on demand, the future of automotive aesthetics is bound to be as exciting as it is innovative.

As these technologies continue to advance, they will likely become more accessible to the average car owner, transforming the way we think about vehicle care and preservation. The days of waxing your car every weekend may soon be a distant memory, replaced by long-lasting, high-tech solutions that keep our vehicles looking showroom-fresh with minimal effort.

In conclusion, the hidden world of automotive paint protection represents a perfect fusion of science, art, and practicality. It’s a field that continues to push the boundaries of materials science and nanotechnology, all in service of preserving the beauty and value of our automotive investments. As we look to the future, one thing is clear: the surface of our cars will be anything but superficial.